双摆软件说明:版本550(中英)本文阐述版本号为550的软件说明,您可以通过监测页面查看系统版本后三位 This article describes the software description for version 550. You can view the last three parts of the system version through the monitoring page

①此界面可以看到当前工艺参数(此页面不可修改工艺)及即时报警信息。 ②开机状态时使能默认为ON,指示红光默认为LINE,焊接模式为连续 关闭使能时,将不会给激光器发送使能信号,可用来试出气功能 关闭红光指示,将不会给电机供电,此时红光为一个点,用于调整中心 焊接模式分为连续和点焊,当选择点焊时,需要在设置页面设置点焊类型 ③安全地锁分为灰色和绿色,当信号接口1的5、6脚短接时,显示为绿色,此时可通过控制信号脚“焊接头出光开关1、2”使其出光。 ① This interface can see the current process parameters (this page cannot modify the process) and instant alarm information. ② Enable the default is ON in the startup state, indicating the red light is LINE by default, and the welding mode is continuous When the enable function is turned off, no enable signal is sent to the laser, which can be used to test the gas function Turning off the red light indicator will not power the motor, and the red light is a point for adjusting the center The welding mode is divided into continuous and spot welding. When selecting spot welding, you need to set the spot welding type on the Settings page (3) The safety lock is divided into gray and green, when the 5 and 6 pins of the signal interface 1 are shorted, it is displayed as green, and at this time, it can be made light by controlling the signal foot "welding head light switch 1, 2".

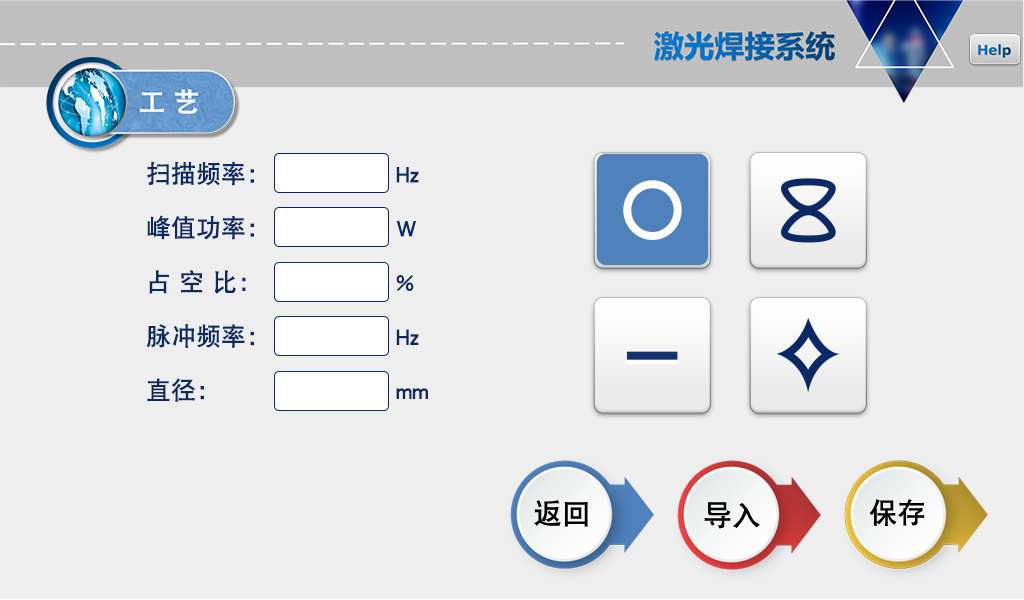

圆形 扫描频率范围:30~200Hz; 峰值功率范围:1W~设置页设置的激光器功率; 占空比范围:0~100;建议100% 脉冲频率范围:5~100000Hz,建议5~5000Hz; 直径:0.01~6mm。 roundness Scanning frequency range: 30 ~ 200Hz; Peak power range: 1W ~ the laser power set on the Settings page; Duty cycle range: 0 ~ 100; Recommended 100% Pulse frequency range: 5 ~ 100000Hz, 5 ~ 5000Hz is recommended; Diameter: 0.01 ~ 6mm.

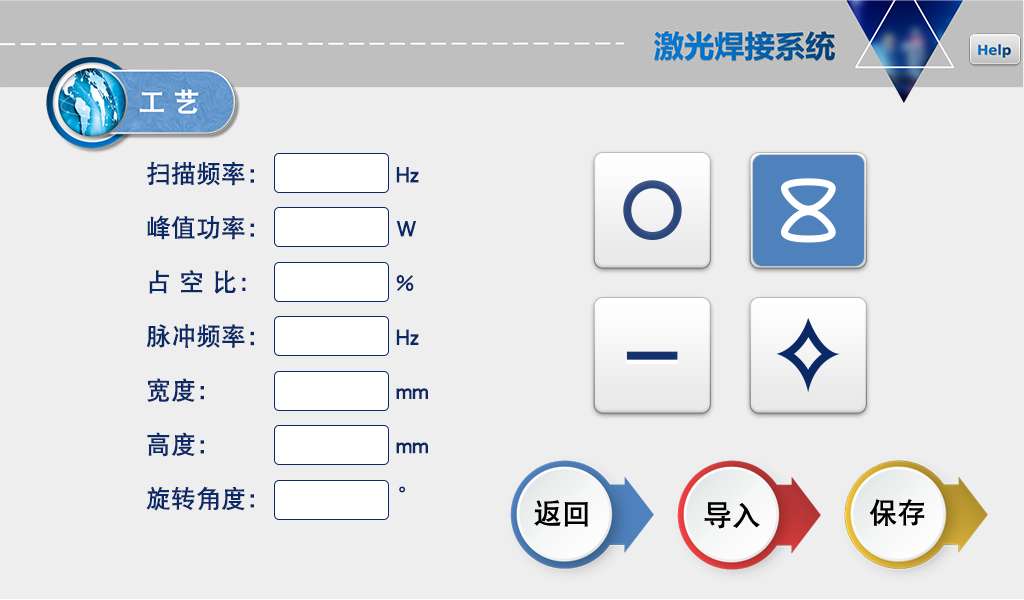

环状 扫描频率范围:30~200Hz; 峰值功率范围:1W~设置页设置的激光器功率; 占空比范围:0~100%;建议100% 脉冲频率范围:5~100000Hz,建议5~5000Hz; 左右宽度:0.01~6mm 上下高度:0.01~6mm 旋转角度:0~360° annular Scanning frequency range: 30 ~ 200Hz; Peak power range: 1W ~ the laser power set on the Settings page; Duty cycle range: 0 ~ 100%; Recommended 100% Pulse frequency range: 5 ~ 100000Hz, 5 ~ 5000Hz is recommended; Width: 0.01 ~ 6mm Upper and lower height: 0.01 ~ 6mm Rotation Angle: 0 ~ 360°

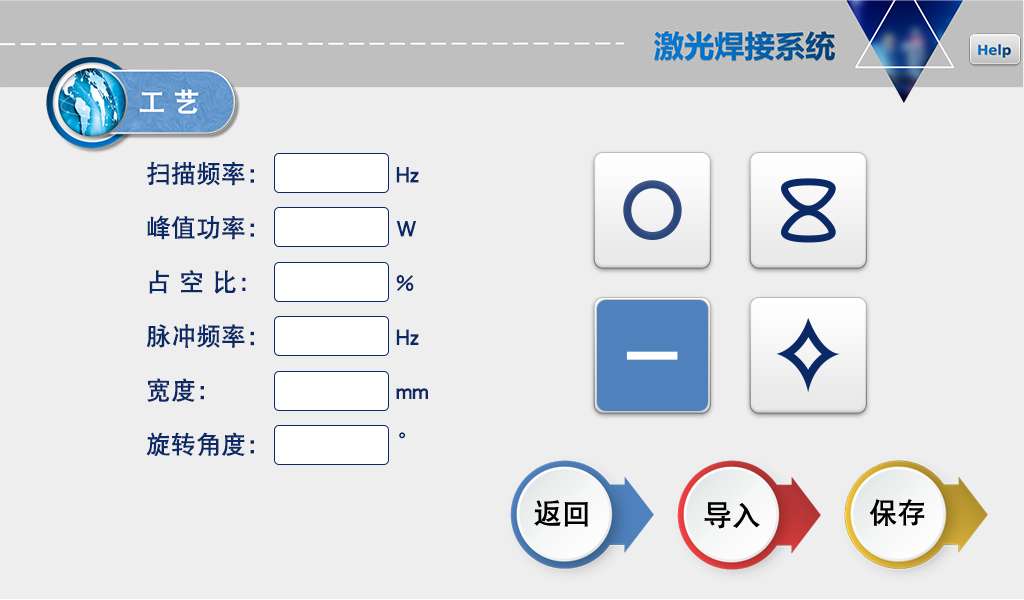

一字 扫描频率范围30~200Hz; 峰值功率范围:1W~设置页设置的激光器功率; 占空比范围:0~100%;建议100% 脉冲频率范围:5~100000Hz,建议5~5000Hz; 宽度:0.01~6mm 旋转角度:0~360° One word Scanning frequency range 30 ~ 200Hz; Peak power range: 1W ~ the laser power set on the Settings page; Duty cycle range: 0 ~ 100%; Recommended 100% Pulse frequency range: 5 ~ 100000Hz, 5 ~ 5000Hz is recommended; Width: 0.01 ~ 6mm Rotation Angle: 0 ~ 360°

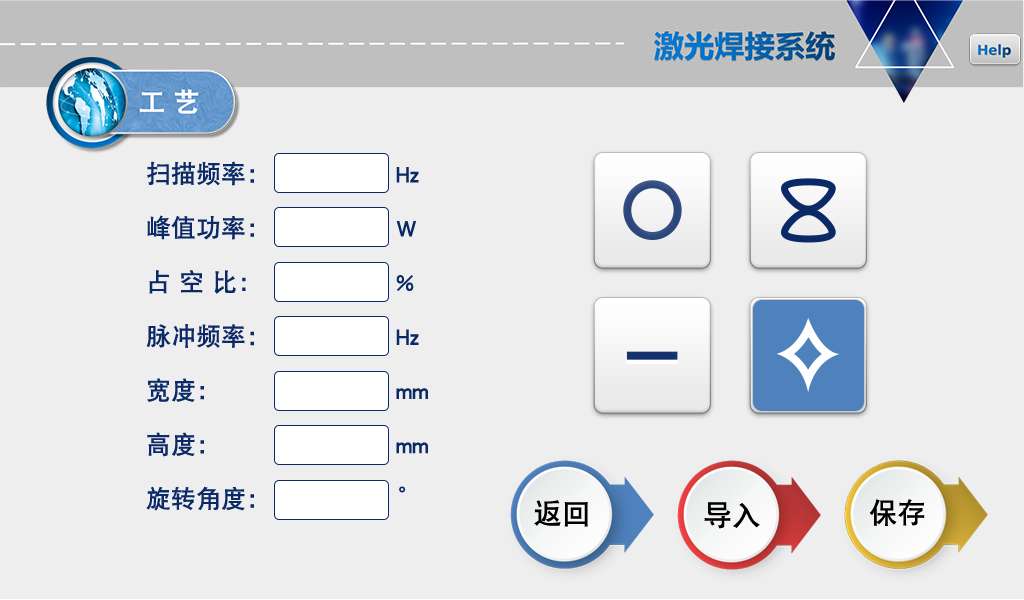

星状 扫描频率范围:40~200Hz; 峰值功率范围:1W~设置页设置的激光器功率; 占空比范围:0~100%;建议100% 脉冲频率范围:5~100000Hz,建议5~5000Hz; 左右宽度:0.01~6mm 上下高度:0.01~6mm 旋转角度:0~360° ①工艺界面包含调试的工艺参数,本版本一共四种图形,点击图形可对光斑形状的工艺进行调整 ②点击框(红色)可修改,修改完毕后点击OK,然后保存,使用时点击导入即可 (修改-保存-导入)。 ③点击右上方的HELP按钮可以获取更多相关参数解释。 ④修改参数后,可在首页查看是否导入成功 ⑤参考工艺,可在小程序的工艺里参考 starlike Scanning frequency range: 40 ~ 200Hz; Peak power range: 1W ~ the laser power set on the Settings page; Duty cycle range: 0 ~ 100%; Recommended 100% Pulse frequency range: 5 ~ 100000Hz, 5 ~ 5000Hz is recommended; Width: 0.01 ~ 6mm Upper and lower height: 0.01 ~ 6mm Rotation Angle: 0 ~ 360° ① The process interface contains the process parameters for debugging. There are four kinds of graphics in this version. Click on the graphics to adjust the process of the spot shape ② Click the box (red) to modify, click OK after modification, and then save, click import when using (modify - save - import). ③ Click the HELP button on the upper right to get more related parameters. ④ After modifying parameters, you can check whether the import is successful on the home page ⑤ Reference process, can be referred to in the process of the small program

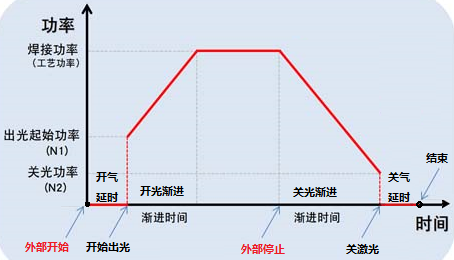

密码123456,每次设置后需要点击保存 ①激光器功率为使用的激光器的功率,请正确填写。 ②开关气延时默认200ms,范围0ms-3000ms。 ③开光时由工艺功率的百分之N1,渐进至100%;关光时由工艺功率的百分之100%, 渐进至N2;(如下图所示)。 Password 123456, you need to click save after each setting ① Laser power indicates the power of the used laser. Enter the correct value. ② Switching gas delay default 200ms, range 0ms-3000ms. ③ When opening light, from 1% of the process power, gradually to 100%; Turn off the light from 100% of the process power, gradually to N2; (as shown in the picture below).

一般预设开关光功率20%,开关光渐进时间200ms ④送丝延时补偿即相对于出光信号的送丝提前时间,可配合回抽功能使用,默认不设置 ⑤温度报警阀值最大65℃,该值设为0时,不检测温度报警。 ⑥扫描校正系数范围0.01~4,系数目标线宽/测量线宽:一般为1。 ⑦激光中心偏移-3~3mm,减小往左移,增大往右移,应用于调整轴红光中心 ⑧气压/水冷机/激光器报警电平信号默认为低电平,当使用此报警信号时,如加装了外部气压报警器则改成高电平有效,否则会出现异常的报警,其他报警信号同理。 ⑨点焊持续时间为当扣动扳机后的出光时间,即使松开按钮,依然会按照出花时间来出光(点焊功能) ⑩点焊间隔时间为扣动扳机按钮后,两次点焊之间的停光时间(点焊功能) ⑧点击右上方的HELP按钮可以获取更多相关参数解释。 Generally, the preset switching optical power is 20%, and the switching optical progressive time is 200ms ④ Wire feed delay compensation is relative to the wire feed advance time of the optical signal, which can be used with the pullback function, and is not set by default ⑤ The maximum temperature alarm threshold is 65℃. When the value is set to 0, the temperature alarm is not detected. 6. The range of scanning correction coefficient is 0.01~4, and the coefficient target line width/measurement line width is generally 1. ⑦ Laser center offset -3~3mm, reduce the shift to the left, increase the shift to the right, applied to adjust the axis red light center Air/water cooler/laser alarm level signal default is low, when using this alarm signal, such as the installation of an external air pressure alarm is changed to a high level effective, otherwise there will be abnormal alarm, other alarm signals the same. ⑨ Spot welding duration is the light time after pulling the trigger, even if the button is released, the light will still be produced according to the time spent (spot welding function) ⑩ Spot welding interval time is the stop light time between two spot welding after pulling the trigger button (spot welding function) ⑧ Click the HELP button on the upper right for more parameter explanation.

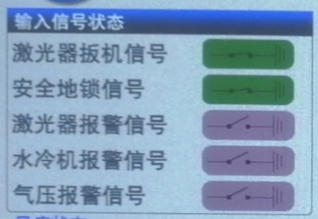

此页面显示了各信号的状态及设备信息,请注意,只有在设置界面为中文的情况下,此监测界面才有显示,否则为其他老版本的监测 ①输入信号状态 激光器扳机信号:当扣动扳机后,此状态由灰色变绿色生效 安全地锁信号:当枪头和安全地锁接触时,此状态由灰色变绿色生效 激光器/水冷机/气压报警信号:监测其设置的高低电平 This page displays the status and device information of each signal. Please note that this monitoring interface is displayed only when the setting interface is in Chinese, otherwise it is for other old versions of monitoring ① Input signal status Laser trigger signal: When the trigger is pulled, this state changes from gray to green Safety lock signal: This status changes from gray to green when the gun head and safety lock are in contact Laser/water cooler/air pressure alarm signal: Monitor its set high and low levels

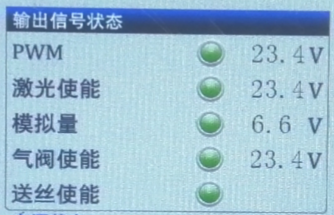

②输出信号状态 当信号输出时,此区域的信号出现改变,可直视化 ② Output signal status When the signal is output, the signal in this area changes and can be directly viewed

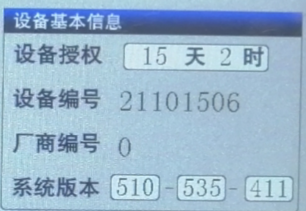

③设备基本信息 设备授权:可对设备进行使用时长授权,当设备使用超过其设定的时间,则显示授权终止, 系统版本:三组数字,第一组为硬件版本,第二组为单片机的程序版本,第三组为触摸屏版本 ③ Basic device information Device authorization: The device can be authorized for the duration of use. When the device is used for more than its set time, the authorization is displayed as terminated. System version: three groups of numbers, the first group is the hardware version, the second group is the program version of the single chip microcomputer, and the third group is the touch screen version

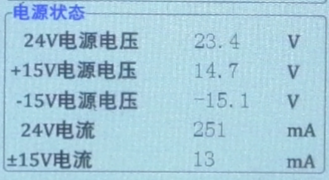

④电源状态 显示了设备此时的输入电压电流 ④ Power status Displays the input voltage and current of the device at this time

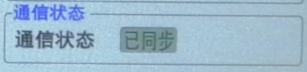

⑤通讯状态 显示了触摸屏和主板的通讯,如出现未同步,则检查连接线 ⑤ Communication status The communication between the touch screen and the motherboard is displayed. If there is no synchronization, check the connection cable

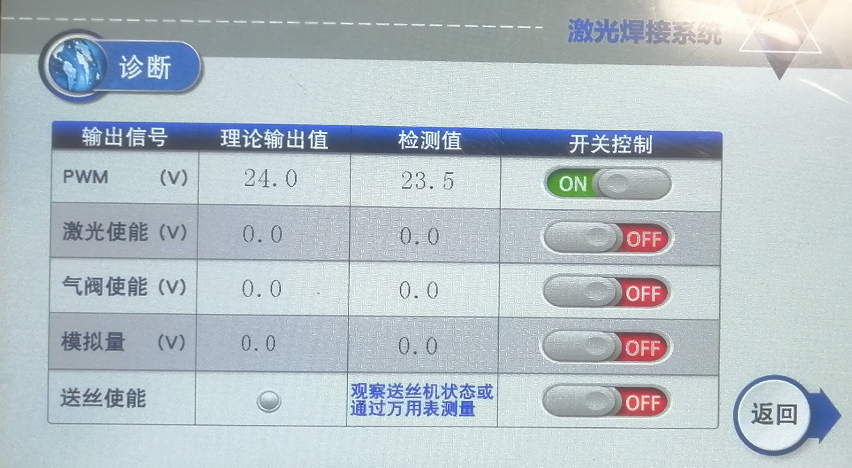

⑥诊断 此界面点击诊断进入诊断界面,用于测量各信号口是否有实际的输出,通常输出值和检测值一致,当不一致时,负载异常,如当激光器不出光时,通过开关单个的端口通过激光器的监测软件或万用表测量,可真实的反馈信号是否发出去 ⑥ Diagnosis Usually, the output value is consistent with the detected value. When the output value is inconsistent, the load is abnormal. For example, when the laser does not emit light, the monitoring software or multimeter of the laser can be used to measure whether the real feedback signal is sent

|