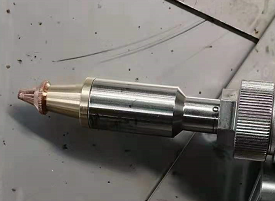

工艺:焊接头切割的参数设置(中英)超强伟业焊接头的切割设置Cutting setup for super weld head 一.铜嘴 使用切割铜嘴(建议铜嘴1.5以上) One. Copper tip Use cutting copper tip (recommended copper tip 1.5 or more)

二.工艺 Ii. Process

与焊接不同的是,切割光斑是没有宽度的,因此扫描宽度务必设置为0,即红光为一个点 其他参数(峰值功率:参考值)(占空比:参考值100%)(脉冲频率:参考1000%)同焊接一致 设置参数后,导入并返回,即可在首页的左侧看到此工艺 焦点建议使用负焦(直接影响切割效果)

三:信号的检测 只有【激光器扳机信号】和【安全地锁信号】有效时,才会出光(激光器状态正常),同时首页未出现任何报警 关于首页的报警,多数是(设置)里面的报警电平设置错误,请更改对应的报警电平 Unlike welding, the cutting spot has no width, so the scanning width must be set to 0, that is, the red light is a point Other parameters (peak power: reference value) (Duty cycle: reference value 100%) (pulse frequency: reference 1000%) are the same as those for welding After setting the parameters, import and return, you can see the process on the left side of the home page Negative focus is recommended (directly affecting the cutting effect) Three: signal detection Only when [laser trigger signal] and [safety lock signal] are effective, light will come out (laser state is normal), and there is no alarm on the home page About the alarm on the home page, most of the alarm levels in the (setting) are wrong, please change the corresponding alarm level 四.红光中心点 务必保证红光完全从铜嘴中心出来,否则可能烧毁铜嘴 一般使用硬件调整,即调整尾部电机 Four. Red light center point Make sure that the red light comes out completely from the center of the copper nozzle, otherwise it may burn the copper nozzle Generally use hardware adjustment, that is, adjust the tail motor 四.切割工件 焦点的要求:负焦相对效果挂渣少 气体的要求:如果对切割面有要求,建议使用氮气气体(大于6公斤),相对切割面发白 如果要求切割厚度,使用氧气或空气切割,相对切割面发黑 不建议使用氩气切割,可能造成切割效果不良

切割厚度:3毫米以下最好

切割时手速保持均匀 Unlike welding, there is no width for cutting spots Therefore, the scan width must be set to 0, i.e. the red light is a dot

Scan speed: Ignore this parameter and feel free to do so Scan width: 0 Peak power: The reference value recommends full power cutting, which is subject to the actual situation Duty cycle: Reference value 100 Pulse frequency: Refer to 1000

Once the parameters are set, import and go back, and you can see the process on the left side of the home page Negative focus is recommended (directly affects the cutting effect)

3. Red light center point Be sure to ensure that the red light comes out completely from the center of the copper nozzle, otherwise the copper nipple may be burned Hardware adjustment is generally used, that is, the tail motor is adjusted For adjustment method, please refer to: Adjusting the red light

Fourth, cut the workpiece The requirements of the focus: the relative effect of the negative focus is less slag Gas requirements: If there is a requirement for the cutting surface, it is recommended to use nitrogen gas (more than 6 kg), which is whitish relative to the cutting surface If the cutting thickness is required, use oxygen or air to cut, and the relative cutting surface is blackened It is not recommended to use argon for cutting, which may cause poor cutting results

Cutting thickness: 3 mm or less is best

Keep your hand speed even when cutting |