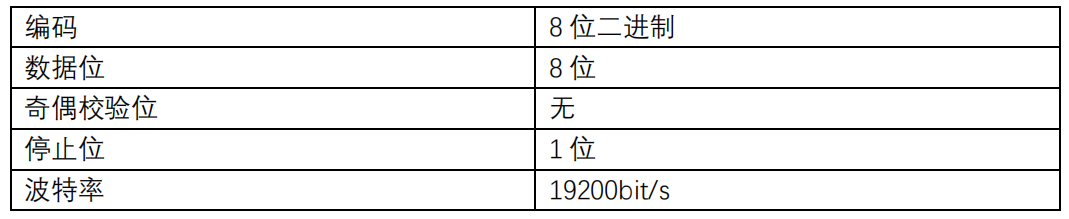

手持焊接:动态参数协议(中英)Handheld welding: Dynamic parameter protocol功能用于机器人通讯,直接修改调用内部参数 本协议兼容 Modbus RTU 规范。 The function is used for robot communication, which directly modifies the internal parameters of the call This Agreement is compatible with the Modbus RTU specification. 一、基本数据格式 1.通讯模块基本参数 First, the basic data format 1. Basic parameters of communication module

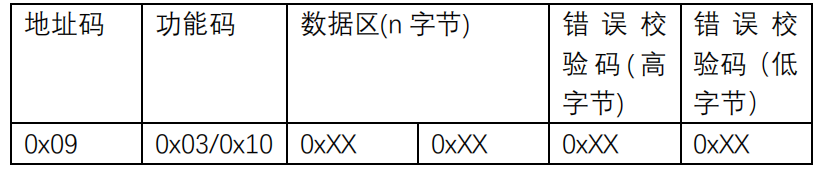

2.数据格式:发送、回执数据格式 2. Data format: send, receipt data format

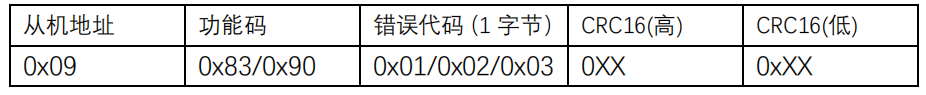

地址码:默认地址为 0x09 ,暂不支持修改 功能码:0x03 读 1 个或多个寄存器 对应的异常回执功能码 0x83 0x10 写 1 个或多个寄存器 对应的异常回执功能码 0x90 数据区:n 个字节,双字节时,高字节在前,低字节在后。 错误校验码:CRC-16/modbus, 高字节在前,低字节在后 Address code: The default address is 0x09, and modification is not supported at this time Function code: 0x03 read the exception receipt function code 0x83 corresponding to 1 or more registers 0x10 write the exception receipt function code 0x90 for 1 or more registers Data area: n bytes, double bytes, high byte first, low byte after. Error checksum: CRC-16/modbus, high byte first, low byte after 错误响应功能码见如下: 错误响应码格式: The error response function code is as follows: Error response code format:

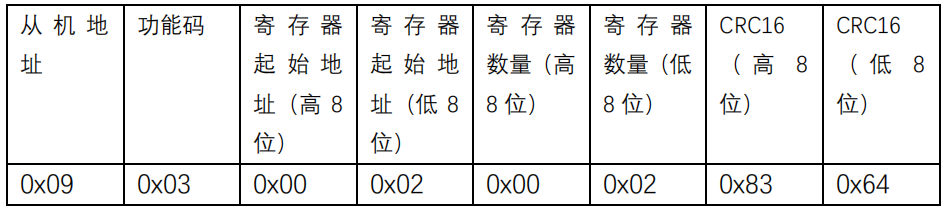

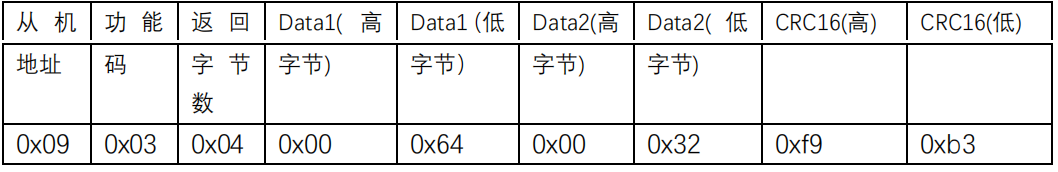

异常功能码对应回执关系: 0x03—0x83 当功能值异常时,回执功能码高位置 1,即:0x83 0x10—0x90 当功能值异常时,回执功能码高位置 1,即:0x90 错误代码:0x01 非法功能 0x02 非法的数据地址 0x03 非法数据值 Exception function code corresponds to receipt relationship: 0x03—0x83 When the function value is abnormal, the receipt function code is high at position 1, that is, 0x83 0x10—0x90 When the function value is abnormal, the receipt function code is high at 1, which is 0x90 Error code: 0x01 Illegal feature 0x02 Illegal data address 0x03 Illegal data value 功能码 0x03-读指令 描述:读寄存器,字节指令操作,可读单个或者多个; 发送指令:如下读取峰值功率和占空比: 从机地址 0x09,寄存器起始地址 0x0002,读 2 个寄存器 Function code 0x03 -Read Instruction Description: Read registers, byte instruction operations, readable single or multiple; Send instructions: Read the peak power and duty cycle as follows: Slave address 0x09, register start address 0x0002, read 2 registers

3)成功响应: 3) Successful response:

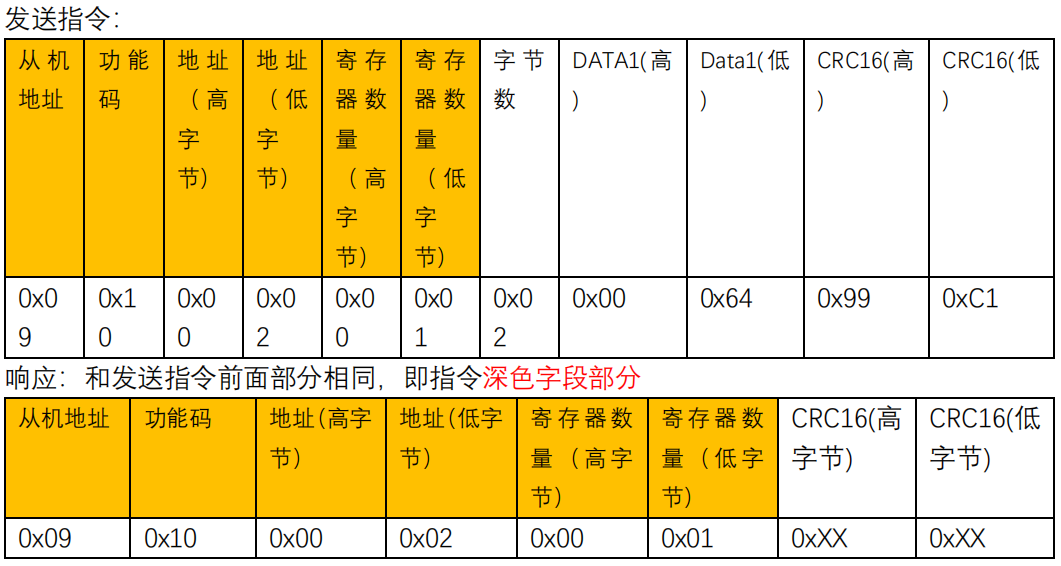

错误响应:见错误响应码格式 06H-写单个寄存器 注:不单独支持,通过如下“写多个寄存器”指令实现 10H-写多个寄存器 描述:写 1 个或多个保持寄存器,字节指令操作,可写多个; 例 1:单独写峰值功率 100w, “峰值功率”寄存器起始地址为 0x0002,写 1 个寄存器,2 个字节的数据,100w 对应的 16 进制为 0x0064 Error Response: See Error Response Code Format 06H - Write a single register Note: Not supported separately, but implemented by the following "Write Multiple Registers" instruction 10H - Write multiple registers Description: Write 1 or more hold registers, byte instruction operations, write multiple; Example 1: Write the peak power of 100w alone, The Peak Power register starts at 0x0002, writes 1 register, 2 bytes of data, and 100w corresponds to a hexadecimal 0x0064

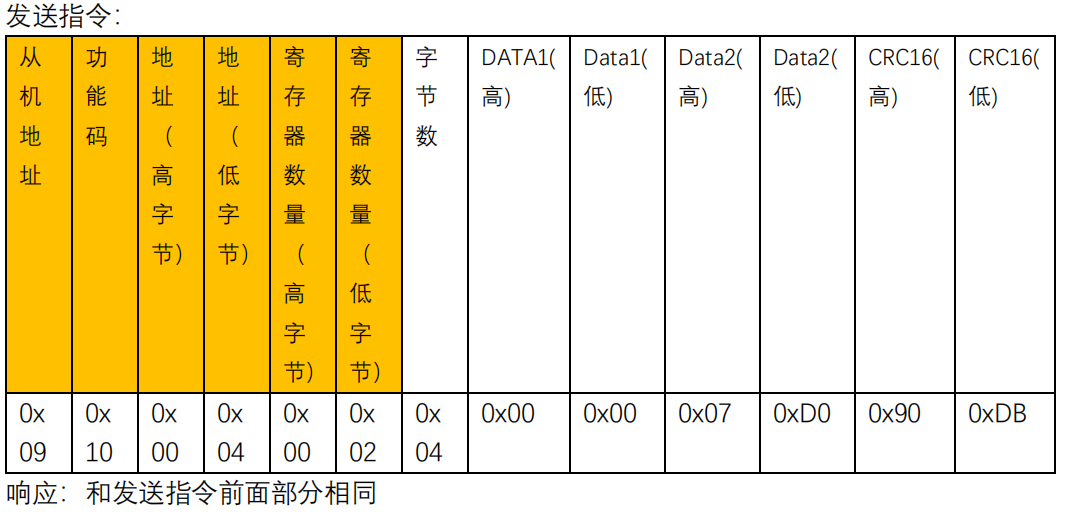

例 2: 写 pwm 频率 2000hz,地址为 0x0004 0x0005 ,寄存器个数 2 个,数据字节数=2 个寄存器* 双字节=4 字节, 即:2000 对应的 16 进制为 0x0000 07d0 Example 2: Write pwm frequency 2000hz, address 0x0004 0x0005, 2 registers, data bytes = 2 registers* Double byte = 4 bytes, i.e. 2000 corresponds to hexadecimal of 0x0000 07d0

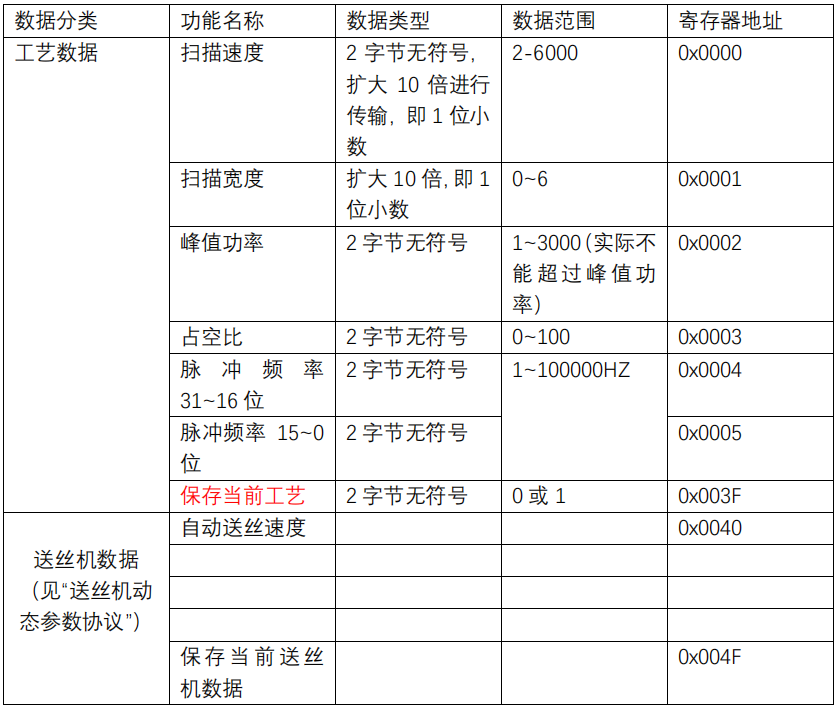

二、寄存器地址 (PLC 或组态地址,在 寄存器地址基础上加十进制 40001,如 0x0000 对应 0x40001,0x0001 对应 0x40002) Second, the register address (PLC or configuration address, in addition to the register address plus decimal 40001, such as 0x0000 corresponding 0x40001, 0x0001 corresponds to 0x40002)

三、使用说明 1.数据间隔:波特率默认为 19200,数据发送 最小时间间隔为 20ms。 2.参数生效:新数据更新后,屏幕界面会立即更新,若设备正处在焊接工作状态,参数会立 即生效,否则进入工作状态时才进行实际生效。 3.参数保存:数据都是作为临时参数,掉电不保存,高频参数变化时,不推荐进行参数实时 保存,容易影响数据发送效率和 flash 寿命。若要保存,发送保存指令,保存指令后,屏幕 工艺界面数据会更新。 3. Instructions for use 1. Data interval: The baud rate defaults to 19200, and the minimum time interval for data sending is 20ms. 2. Parameters take effect: After the new data is updated, the screen interface will be updated immediately, if the equipment is in the welding work state, the parameters will stand that is, it takes effect, otherwise it will only take effect when it enters the working state. 3. Parameter preservation: The data is used as a temporary parameter, the power failure is not saved, and when the high-frequency parameters change, it is not recommended to carry out the parameter in real time Saving, easy to affect the data transmission efficiency and flash life. To save, send a save instruction, after saving the instruction, on the screen Process interface data is updated. 三、常用指令举例 1. 单独 扫描宽度 设置 1mm 发送:09 10 00 01 00 01 02 00 0a 46 40 2mm 发送:09 10 00 01 00 01 02 00 14 4e c0 3mm 发送:09 10 00 01 00 01 02 00 1e 49 40 4.1mm 发送:09 10 00 01 00 01 02 00 28 5f c0 5mm 发送:09 10 00 01 00 01 02 00 32 94 41 3. Examples of commonly used directives 1. Separate Scan width setting 1mm Send: 09 10 00 01 00 01 02 00 0a 46 40 2mm send: 09 10 00 01 00 01 02 00 14 4e c0 3mm Send: 09 10 00 01 00 01 02 00 1e 49 40 4.1mm Send: 09 10 00 01 00 01 02 00 28 5f c0 5mm Send: 09 10 00 01 00 01 02 00 32 94 41 2.单独峰值功率 设置 100W: 09 10 00 02 00 01 02 00 64 99 c1 200W:09 10 00 02 00 01 02 00 c8 e4 c1 300W:09 10 00 02 00 01 02 01 2c 3f c0 400W:09 10 00 02 00 01 02 01 90 8e c1 500W:09 10 00 02 00 01 02 01 f4 65 c0 600W:09 10 00 02 00 01 02 02 58 e8 c0 2. Individual peak power settings 100W: 09 10 00 02 00 01 02 00 64 99 c1 200W:09 10 00 02 00 01 02 00 c8 e4 c1 300W:09 10 00 02 00 01 02 01 2c 3f c0 400W:09 10 00 02 00 01 02 01 90 8e c1 500W:09 10 00 02 00 01 02 01 f4 65 c0 600W:09 10 00 02 00 01 02 02 58 e8 c0 3.单独占空比 设置 50%占空比:09 10 00 03 00 01 02 00 32 76 40 3. Separate duty cycle settings 50% duty cycle: 09 10 00 03 00 01 02 00 32 76 40 4.单独脉冲频率 设置 2000HZ: 09 10 00 04 00 02 04 00 00 07 d0 90 db 4. Individual pulse frequency settings 2000HZ: 09 10 00 04 00 02 04 00 00 07 d0 90 db 5.同时设置扫描宽度和扫描速度 1mm 100mm/s:09 10 00 00 00 02 04 03 e8 00 0a b8 d9 2mm 200mm/s:09 10 00 00 00 02 04 07 d0 00 14 4d d9 3mm 300mm/s:09 10 00 00 00 02 04 0b b8 00 1e c6 db 5. Set the scanning width and scanning speed at the same time 1mm 100mm/s:09 10 00 00 00 02 04 03 e8 00 0a b8 d9 2mm 200mm/s:09 10 00 00 00 02 04 07 d0 00 14 4d d9 3mm 300mm/s:09 10 00 00 00 02 04 0b b8 00 1e c6 db |