工艺:焊接头清洗的参数设置(中英)超期伟业焊接头的清洗参数设置 一.系统的接线 清洗版接线与焊接版没有差别,可参考其接线部分:SUP20S说明书‍ (信号接口一的5/6脚短接,使其安全地锁有效,扣动扳机按钮后即出光) 二.工艺设置 Cleaning parameter setting of extended welding joint I. Wiring of the system There is no difference between the cleaning version and the welding version, you can refer to its wiring part: SUP20S manual ‍ (The 5/6 pin of signal interface 1 is shorted to make the safe lock effective, and the light comes out immediately after the trigger button is pulled) 2. Process setting

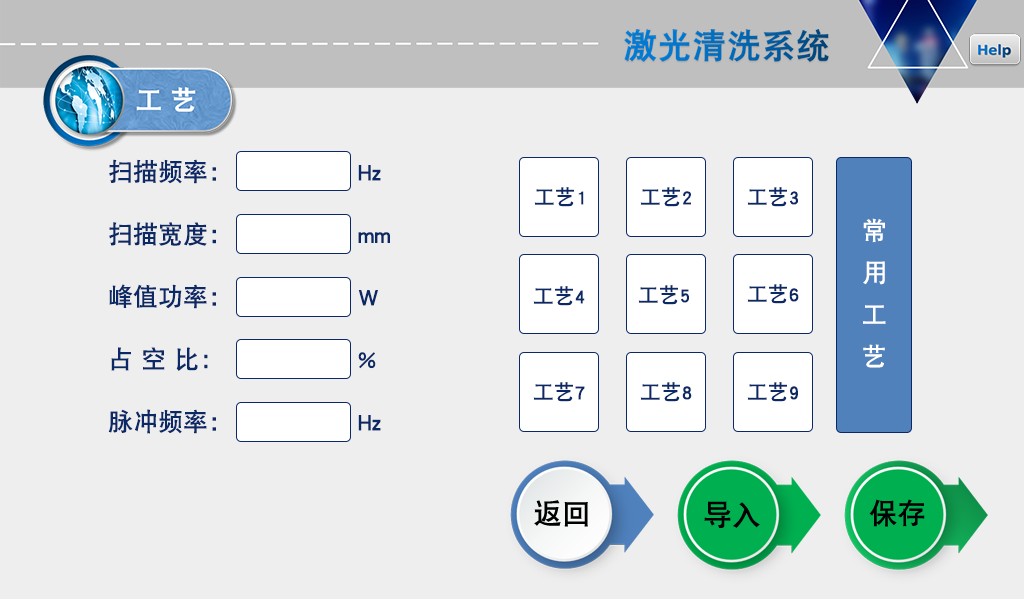

清洗工艺 扫描频率:电机的摆动速度,范围10-100Hz,建议设置50 扫描宽度:光板的扫描宽度,范围0-150mm,建议设置150 占空比:默认100% 脉冲频率:默认2000 设置参数后,导入并返回,即可在首页的左侧看到此工艺 ②焦点的确认 通过来回近远距离的扫描,在声音最大,火花最大时即为焦点,此时应按照这个距离进行清洗,能量最强 (一般枪头到板材的距离为30厘米左右能量最强) Cleaning process Scanning frequency: motor swing speed, range 10-100Hz, recommended to set 50 Scanning width: The scanning width of the light plate, the range is 0-150mm, 150 is recommended Duty cycle: 100% by default Pulse frequency: Default 2000 After setting the parameters, import and return, you can see the process on the left side of the home page ② Confirmation of focus By scanning back and forth near and far, it is the focus when the sound is the largest and the spark is the largest, and it should be cleaned according to this distance and the energy is the strongest (Generally, the distance between the gun head and the plate is about 30 cm, and the energy is strongest)

③信号的检测 只有【激光器扳机信号】和【安全地锁信号】有效时,才会出光(激光器状态正常),同时首页未出现任何报警 关于首页的报警,多数是(设置)里面的报警电平设置错误,请更改对应的报警电平 清洗时请保持枪头到板材的距离平稳,手速保持均匀 ③ Signal detection Only when [laser trigger signal] and [safety lock signal] are effective, light will come out (laser state is normal), and there is no alarm on the home page About the alarm on the home page, most of the alarm levels in the (setting) are wrong, please change the corresponding alarm level When cleaning, keep the distance from the gun head to the plate steady, and keep the hand speed even |